What are different types of transformer cooling methods?

Different types of transformer cooling methods are available and those methods are mainly chosen based on the transformer power ratings.

- Dry-type

- Air Natural (AN)

- Air Forced (AF)

- Oil-immersed

- Oil Natural Air Natural (ONAN)

- Oil Natural Air Forced (ONAF)

- Oil Forced Air Natural (OFAN)

- Oil Forced Air Forced (OFAF)

- Oil Natural Water Forced (ONWF)

- Oil Forced Water Forced (OFWF)

AN, ONAN, ONAF are commonly used methods that can easily find in distribution and power transformers.

Why transformer needs a cooling mechanism?

Because unlike a no-loss ideal transformer a practical transformer has a number of losses like copper loss, iron loss, etc where the majority of it causes the heating of the transformer core and the windings. Also, warmer weather and overloading will aggregate the rate of heating. This excessive heating causes damage to insulations, winding coils, transformer parts, etc. Hence necessary cooling methods are essential to limit the temperature of the transformer in a safe operating range.

Air Natural (AN)

Most low-power transformers cool by air natural method, where the transformer core is exposed to air which will dissipate the heat to the surrounding air.

It is simple as any object with high temperature than atmospheric temperature will cool itself by natural convection. The air circulates naturally as the hot air move upwards and replaced by cool air.

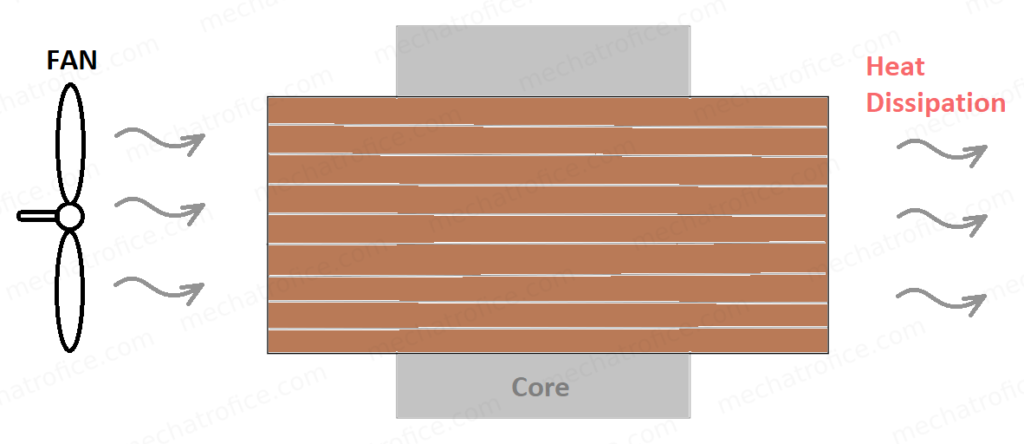

Air Forced (AF)

In this method, an additional fan is used to give a forced air to the transformer to increase the rate of cooling or heat dissipation.

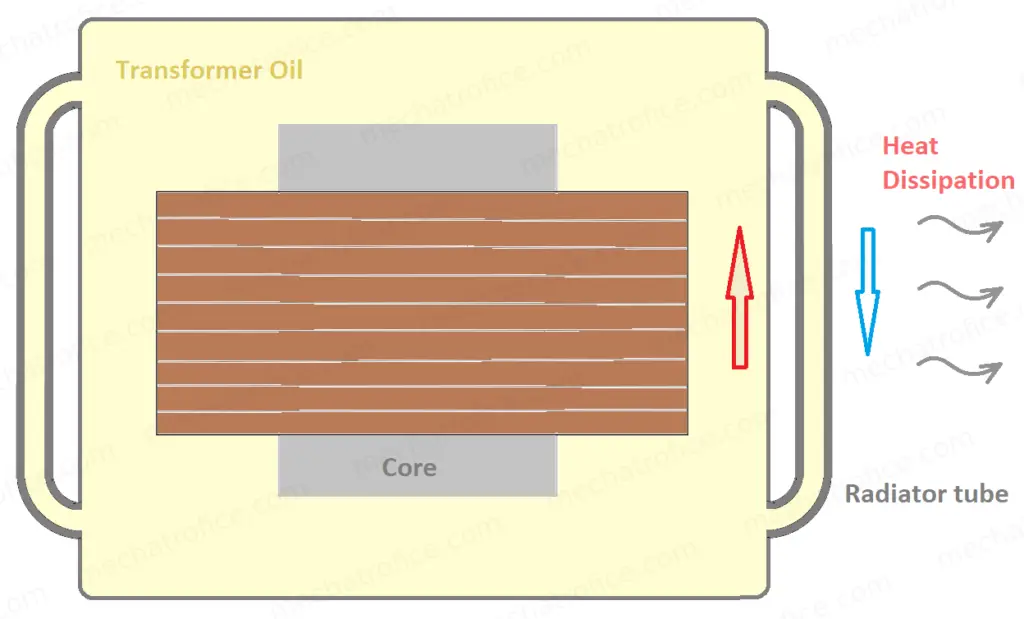

Oil Natural Air Natural (ONAN)

In this type of transformers, the winding is immersed in the oil. Hence the heat dissipated from the winding and core will be transferred to the oil. The oil-immersed transformers have a radiator, the hot oil moves up and flows to the radiator by means of convection. In the radiator, the oil cools as the heat dissipated through the radiator fins to the surrounding air (air natural) and the cooled oil then moves to the downside. This natural movement of oil continues and thereby the heat transfer.

Transformers used in distribution lines usually have this type of cooling that is HT/LT transformer like 11KV/230V that has a rating of.

Oil Natural Air Forced (ONAF)

In this method, the oil transfers heat by natural convection but an additional forced air is provided to the fins of the radiator to increase the rate of heat dissipation.

This a common type of cooling in a transformer used in electrical substations which converts EHT to HT, like 110KV to 33KV, 110KV to 11KV, 66KV to 11KV that has a rating of 10MVA, 20MVA, etc.

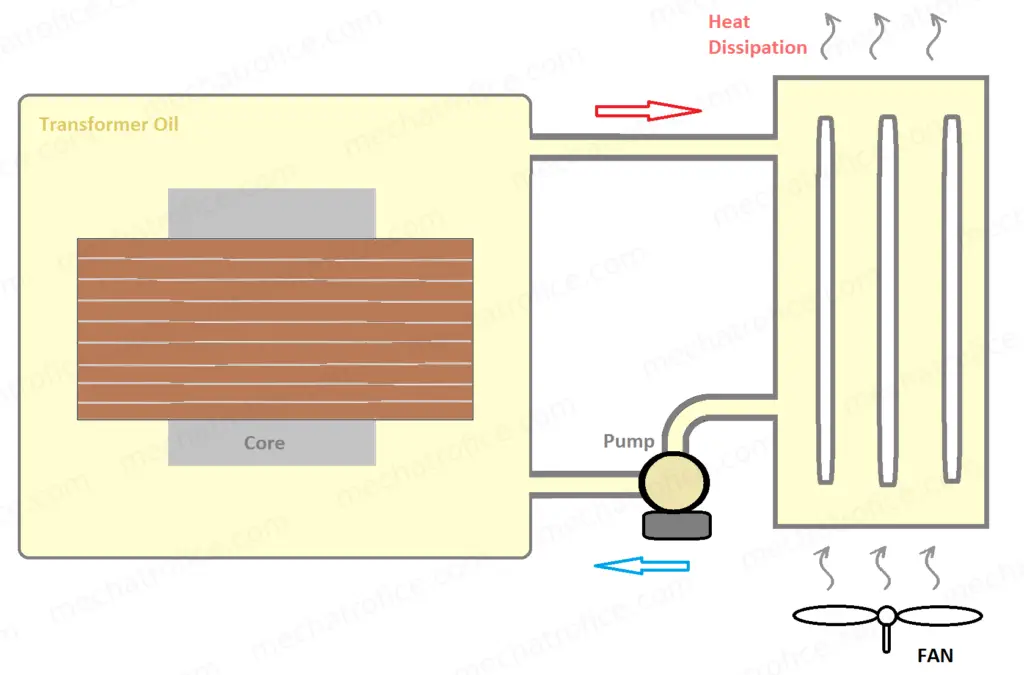

Oil Forced Air Natural (OFAN)

The oil is pumped to the radiator using an oil pump which then cools by surrounding air. Here the transfer of heat from the transformer core and surroundings will occur at a faster rate as the oil movement is forced.

Oil Forced Air Forced (OFAF)

Here along with the forced oil, it has a forced-air cooling which further increases the cooling rate.

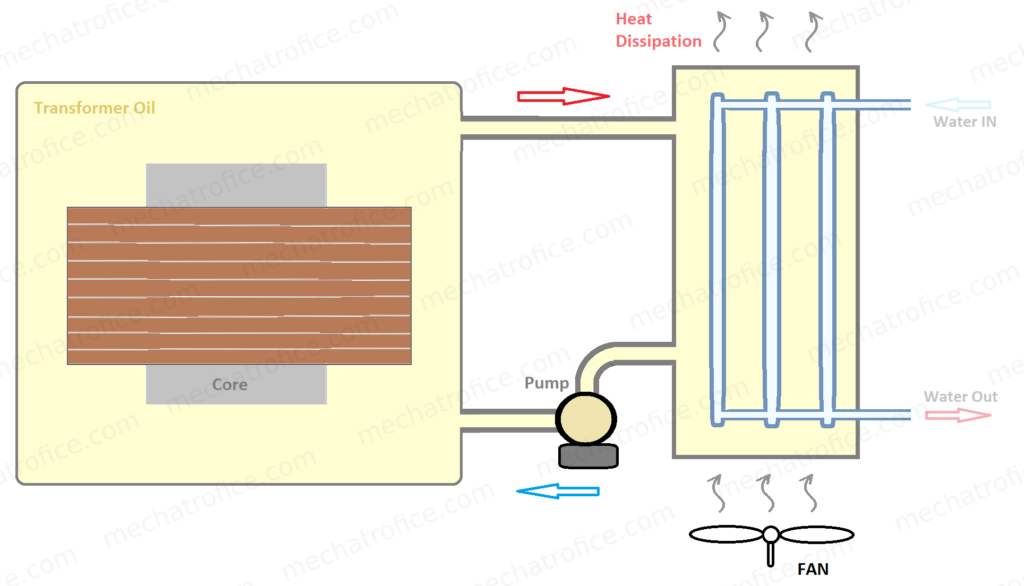

ONWF

The oil naturally moves to the water heat exchanger and the water act as the medium for heat exchange. The heat is transferred to the cold water that enters from one direction and exists through another as hot water.

OFWF

Here instead of natural flow, the oil is pumped to the water heat exchanger.

The airflow fans, pump, etc of the cooling mechanisms are controlled either automatically or manually. In an automatic system, the sensor and relay control automatically switch ON and OFF the cooling mechanism, whereas in manual control the temperature changes are required to be measured periodically and the cooling mechanisms are manually operated.

The actual arrangements of transformer parts, parts of cooling mechanisms like radiators, fans, etc, and the direction of flow of air, oil, water, etc are entirely different from the above images. All images provided are only for presenting the concept and easy understanding.

Awesome

cool