Electric Motor Interview Viva Questions and Answers

What is an Electric motor?

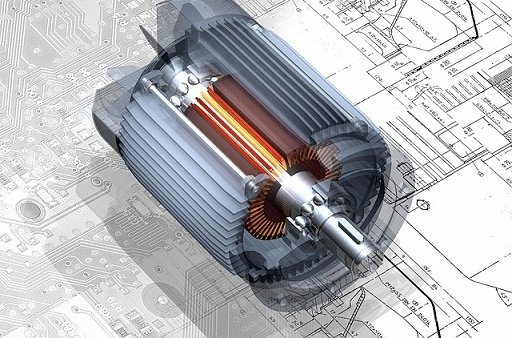

An electric motor is an electrical machine that converts electrical energy into mechanical energy.

What are ac and dc motors?

The electric motor that converts the AC electrical energy into mechanical energy by using an electromagnetic induction phenomenon is called an AC motor.

Electrical machines that convert DC electrical energy into mechanical energy is known as a DC motor.

What is a universal motor?

The universal motor is a type of electric motor that can operate on either AC or DC supply. A universal or AC series motor is similar to a DC series motor which has an armature and field windings connected in series. Since the field flux and armature current reverse simultaneously, the direction of torque always remains the same irrespective of its polarity.

DC motor

Brushed DC electric motor

By Abnormaal – Own work, CC BY-SA 3.0, Link

By Abnormaal – Own work, CC BY-SA 3.0, Link

What are the different types of DC motors?

- Self Excited DC Motor

- Shunt-wound motor – The field winding is connected in parallel with the armature winding. (figure A)

- Series wound motor – The field winding is connected in series with the armature winding. (figure B)

- Compound wound motor – Motor consist of two field windings. One connected in parallel and other in series to the armature.

- Short shunt compound motor – The shunt field winding is connected parallel to the armature and series winding is in series to these parallel circuits.

- Long shunt compound motor – In long shunt, the armature is connected in series with the series winding and the shunt field winding is parallel to this connection. (figure C)

By Sefid par – Own work, CC BY-SA 3.0, Link

Both short shunt and long shunt are of two types; Cumulative Compound Motor – aids the field flux each other and Differential Compound Motor – opposes the field flux each other respectively.

- Separately Excited DC Motor

The field windings and armature windings are powered by separate DC supplies.

What are the types of armature windings in DC motor?

Wave winding – In this type of winding the armature winding is divided into two parallel paths irrespective of the number of poles.

Lap winding – Armature winding is divided into parallel paths equal to the number of poles.

What are the losses in a DC motor?

- Copper loss – Coppes loss in armature and field windings; Cu loss = I R. (Brush loss are included with the armature loss)

- Iron loss – Loss due to hysteresis and eddy current loss.

- Mechanical loss – friction – due to bearings, brush, similar mechanical parts, and windage loss – air friction of rotating parts.

What is called armature reaction in DC motors?

There are two kinds of flux present in a DC machine, main flux (flux due to the armature conductors) and armature flux (flux due to the field winding). The effect of armature flux on the main flux is known as armature reaction, which weakens the net field flux.

The armature reaction takes place in both DC motors and generators.

What is called back emf in dc motor?

When the armature conductor moves through the magnetic field an emf is induced in opposite to the applied voltage and is known as back emf.

Back emf, Eb = PФZN/60A

P – Number of poles

Ф – Magnetic flux per pole

Z – Total number of armature conductors

N – Armature speed in r.p.m

A – Number of parallel paths

What are the characteristics of a DC motor?

- Torque vs Armature current characteristics – It is a characteristic curve between torque Ta and armature current Ia (Ta/Ia).

- Speed vs Armature current characteristics – The characteristic curve between speed Na and armature current Ia (N/Ia).

- Speed vs Torque characteristics – Characteristic curve between speed N and torque Ta (N/Ta).

What are the speed control methods of DC motors?

Flux control method – The speed of the motor is controlled by varying the flux due to the field windings; the speed of the armature is inversely proportional to the flux.

Armature control methods – This method is by adding resistance to the armature circuit to vary the voltage available across the armature.

What are the applications of DC motors?

Series Motor used for applications that require high starting torque – Cranes, Elevators, Air compressor, Sewing machine, etc

Shunt motor for constant speed applications – Lathe Machines, Conveyors, Weaving Machine, Centrifugal Pumps, Spinning machines, Drills, etc.

Compound motors used for higher starting torque and almost constant speed – Presses, Shears, Rolling Mills, etc.

What are the industrial applications of DC motor over AC motors?

AC

What is a 3Ф Induction motor?

A 3 phase motor also called as an asynchronous motor is an electrical machine operates on the production of rotating magnetic field. The 3 phase induction motor also consists of a stator and rotor. The stator of the 3Ф induction motor is connected to a 3 phase supply and the rotor consists of a short-circuited winding. The rotor of an induction motor is like a shorted secondary of a transformer which energizes from the stator winding through electromagnetic induction. It is unlike from other motors like a DC motor, synchronous motor, etc… which has both the rotor and stator are connected to the power supply.

What are the types of 3 phase induction motor?

- Squirrel Cage Rotor – It consists of cylindrical laminated core rotor having parallel slots with heavy copper or aluminum bars in each slot. All the bars are permanently short-circuited with end rings and no external resistance can be added to the rotor conductors.

- Wound or Slip Ring Rotor – It has a laminated cylindrical core with uniformly distributed windings similar to the stator windings. The end of the rotor windings is connected to three slip rings which can be connected to external resistance through brushes connected to each slip rings. This external resistance is used to obtain high starting torque. At the starting, the brushes will be connected to a star connected rheostat and short-circuited when the motor attains its normal speed.

what is called slip in a motor?

The difference between the synchronous speed Ns of the rotating field and the rotor speed N of the induction motor is called slip. It is usually expressed as a percentage of synchronous speed Ns.

What is a synchronous motor?

A synchronous motor is a motor that runs at synchronous speed.

Synchronous speed, Ns = 120 * f / p

f – Frequency of the supply

P – Number of poles

What is called synchronous capacitor?

A synchronous capacitor or a synchronous condenser is an over-excited synchronous motor which is free running or running on no load.

List a few advantages and disadvantages of squirrel cage and slip ring induction motor?

- Squirrel cage

- Advantage

- Simple and rugged construction.

- Low cost.

- Less maintenance.

- It can operate nearly at a constant speed.

- High overload capacity.

- Operates at better power factor.

- Disadvantage

- Poor starting torque.

- High starting currents.

- No speed regulation.

- Slip ring

- Advantage

- High starting torque

- Low starting current

- Speed regulation.

- Disadvantage

- High initial and maintenance cost.

- Poor power factor at light loads.

- Sensitive to voltage fluctuations.

- Advantage

- Advantage

Reference

What does Aislam on a 3 ph AC motor refer to.

nice, thanks dude.