Why a capacitor is used with a single phase fan or motor?

A single phase induction motor is not a self-starting motor, so it requires some starting means for working. That is an initial torque is required for the motor to get started. The starting torque can be given to the motor by applying a mechanical rotation to the motor shaft. Once the motor has started it can continue its rotation unless its supply is OFF. But the mechanical starting is not always convenient and easy, especially for large motors, ceiling fans fixed at heights, etc. Thus we have to employ some electrical methods to self-start the motor.

In a single phase motor, the field created by the stator winding is positive on one-half cycle and negative in the other half cycle. It will produce a magnetic field that pulsates in sinusoidal which results the net field becomes zero. That is the field polarity reverses after each half cycle, but the field does not rotate; thus the torque is zero.

The role of a capacitor

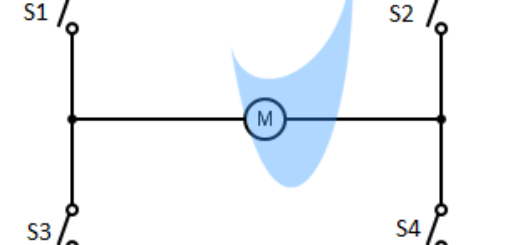

There must be a revolving magnetic field or rotating magnetic field to create a torque for rotating the rotor. To generate a revolving magnetic field two or more phase line is required. So in an induction motor, a two-phase supply has created from a single phase supply with the help of additional starting windings or auxiliary winding along with a capacitor.

In Ideal case, the additional auxiliary winding of a stator with a capacitor, create a phase difference of 90 degrees to the main winding. The two fields which are almost 90 degrees to each other, creates a rotating magnetic field which starts the motor. The capacitor value should select to obtain a starting winding current which leads 80 degrees with respect to the main winding current.

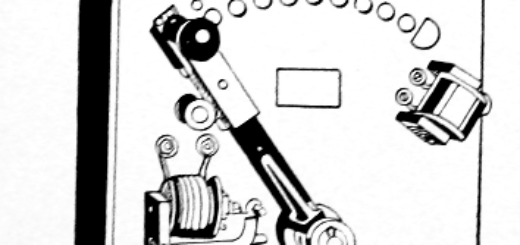

As mentioned before, a mechanically applied starting torque is enough to start the motor. And the motor can continue its rotation when the rotor has enough speed to keep rotating. Similarly, once the motor has rotated a forward field can maintain a positive torque for rotation. So the auxiliary winding with the capacitor can now be removed from the circuit. When the motor attains a sufficient speed, i.e. 75% to 80% of synchronous speed, the centrifugal switch opens the starting winding from the supply. Such type of induction motor arrangement is called as capacitor start induction motors.

Another type of induction motors is capacitor start-capacitor run motors. It has a permanent connection with the starting winding along with the capacitor to the supply. These motors have no centrifugal switch as it does not disconnect the starting winding, it uses the winding for both the starting and running. Capacitor start-capacitor run motors have Improved efficiency and power factor.

Very well explained. I loved the simplicity in words while reading….

Best explanation!

Completely satisfied