Why transformer cores are made of thin laminated sheets?

A practical transformer has different types of losses like core loss, copper loss, etc, that decrease the efficient transfer of energy from the primary to the secondary coil.

Eddy current loss is one of the core losses that affect the performance of a transformer by heating from electromagnetic induction. An Eddy current is a closed loop of electrical current induced within a conductive material due to a changing magnetic field.

In a transformer, the core doesn’t need to have any current flow as it is a magnetic circuit, not an electrical circuit. But as the core is metallic or made of a conductive material that is placed inside a changing magnetic field an eddy current will be definitely produced in it. These currents generate heating in the core and result in power loss in a transformer in the form of heat energy.

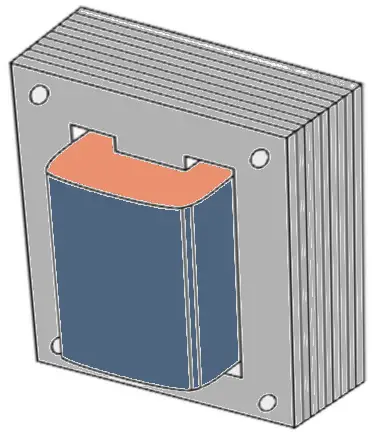

So, in order to reduce eddy current loss, the circulating current need to be minimized by increasing the core resistance. The code resistance can be increased by making the core with thin laminated sheets. The lamination creates insulation between each sheet which makes each sheet a separate electrical conductor but lets the magnetic flux to pass. So, compared to a single block of the core, thin laminated sheets increase the resistance of the core and thereby reduces the amount of current flowing through the core. Whereas a solid core results in excessive eddy current and heat loss.

A laminated core of a transformer helps to minimize the energy losses due to eddy currents and improves the transformer efficiency.